wide spectrum for spin, burst, overspeed, containment, vibration, flow and more

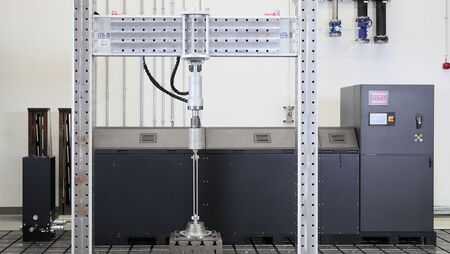

The perfect engine is the result of perfect parts. Which is why MTU only uses components that have been rigorously and successfully tested. All mechanical component tests are conducted in a representative environment, using engine conditions with realistic loads and temperatures.

MTU performs a wide spectrum of tests on rotating and static parts, such as cyclic spin tests with LCF and HCF loads, overspeed / burst tests, containment tests, vibrational fatigue and modal analysis, ballistics, structural tests and flow tests. We have a broad range of heating systems for each test field, including induction heating, as well as a complete range of standard to high-end measurement equipment.

Contact