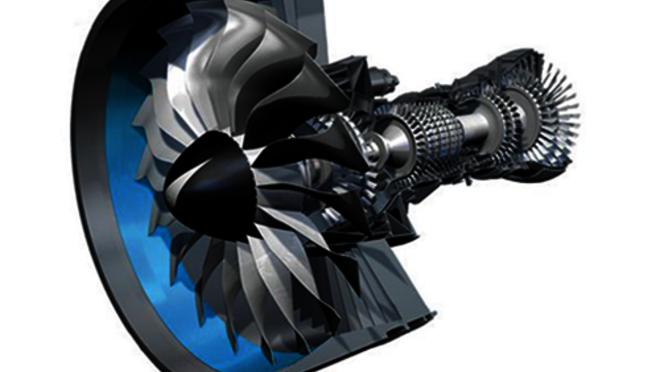

Brush seals: Aircraft Engines

Standard in next-generation aircraft engines

MTU brush seals find homes mainly in aircraft engines. They have indeed proved their worth in operation, having accumulated well over 7.5 million running cycles in advanced aircraft engines as:

- shaft seals

- static seal members

- bearing chambers or rotor wheel seals

Our long-standing experience enables us to provide custom-tailored solutions for all aircraft engine applications and for almost every area of the engine.

MTU’s innovative seals have also found a home in Pratt & Whitney’s next-generation geared turbofan engines. All PurePower PW1000G family engines come equipped with brush seals made by MTU. The PW110G-JM engine to power the Airbus A320neo alone will incorporate MTU’s seals at four locations. Compared with labyrinth seals, MTU’s brush seals have halved cooling air losses at all installation positions in the engine, which results in:

- enhanced efficiency

- reduced fuel burn

- reduced CO2 emissions

- more compact design

MTU brush seals as semi-static seals

One innovation developed by the MTU experts is the semi-static brush seal. In this field of application, MTU brush seals are used to seal off non-rotating parts of a machine in operation by compensating movements of several millimeters and high differential pressures in a mostly hot environment of up to 700 degrees Celsius.